Paraglider In-Flight line Tuners

The PROBLEM

Ozone Paragliders approached us with a problem: when test-flying a new prototype glider, often there is a need to trim the glider by making small adjustments to line lengths.

At the moment this is done by flying the glider to test it, landing, looping lines when necessary, and flying again, repeating the process as many times as necessary until the glider is in trim.

This process can take weeks and months for various prototypes, so test pilots could save a lot of time (and, as a consequence, money) by having a way to adjust individual line lengths in-flight.

Initial ideas

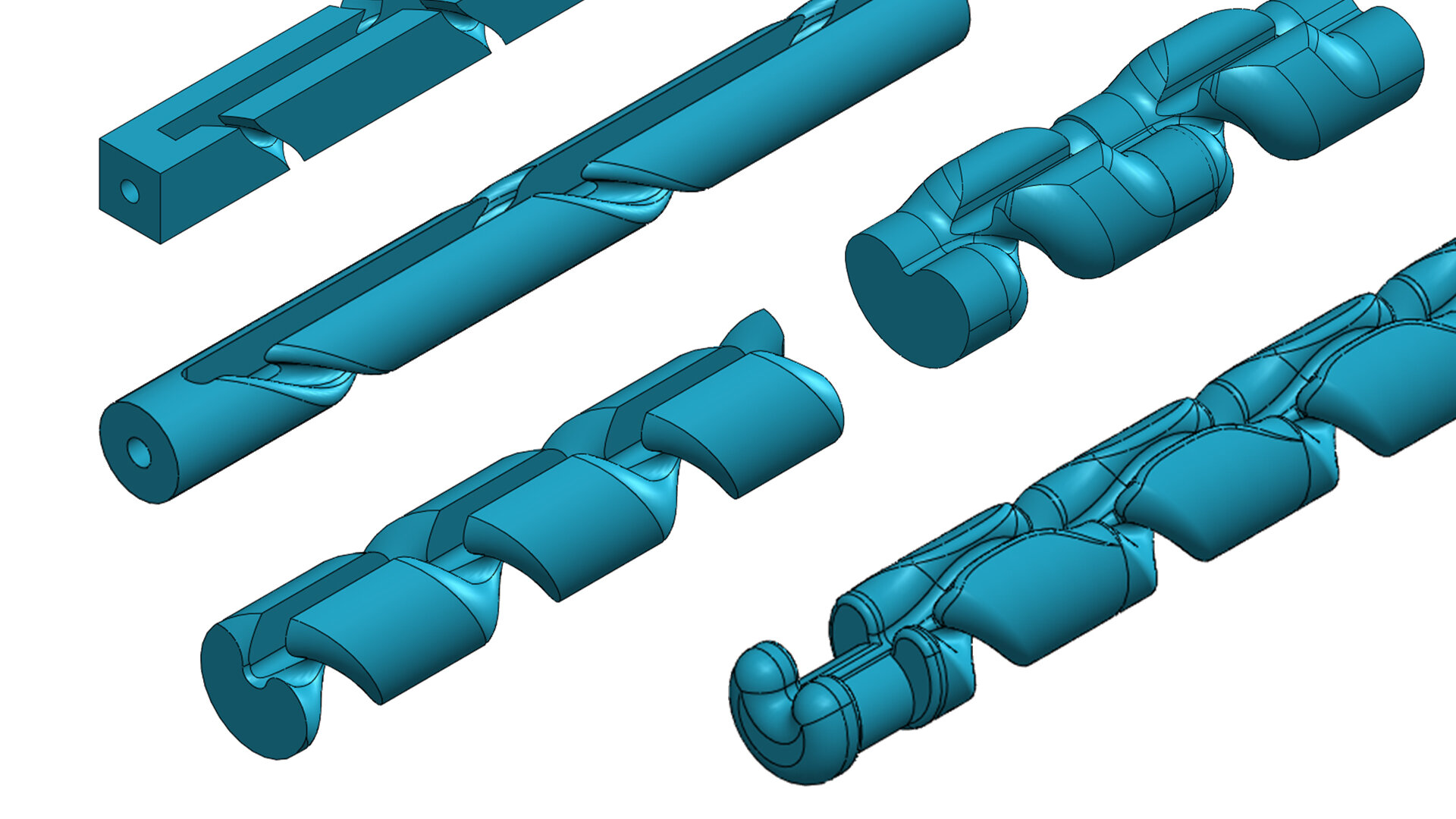

We brainstormed ideas, sketched concepts, and produced some simple examples, from common existing mechanisms to more exotic ones.

The concepts were then ranked according to various parameters such as safety, ergonomics, cost, complexity, etc. Then the highest ranking concepts were developed further to an MVP to be evaluated again so a winning idea could be chosen to take forward into further prototyping.

Refining the design

The “spiral” concept scored the highest so it was developed further. This was not only to understand the relationship between shape and line shortening, but also the ergonomics of use in-flight as well as structural integrity.

After 9 iterations we arrived at a design that seemed to tick most of the boxes. Also different versions were created with different numbers of turns and with larger or smaller line shortening amounts.

First products

The latest designs were made in a variety of materials & coatings. This allows us to test a wide range of options and will allow us to quickly change the design or manufacturing process to make the tuners better suited for their intended application.

In addition, the tuners can be made in different length reduction amounts, with fewer or more turns, and can be optimised for different line diameters, making the length reduction more accurate.

Testing

The first batch of working prototypes went to the R&D team at Ozone and got tested in the air to help develop and trim future Ozone wings.

The feedback was that the prototypes worked but they were not quite strong enough for every day use and the line retention method could be improved.

Final Products

By changing the material to industrial nylon the tuners are now much stronger as well as have a much better way to retain the tuners on the lines. The failure method is always the line breaks before the tuners and they can definitely take a beating!

A few different paraglider manufacturers have been testing them so if you want to get some yourself just send us a message on the form below.

GET IN TOUCH

If you’re interested in this product or want to discuss a brand new project just send us a message and we’ll get back to you!